Exploring Unique Alternatives to Traditional LED Wiring Harness Solutions

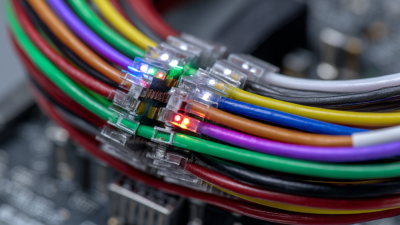

In the rapidly evolving landscape of automotive and industrial lighting solutions, the quest for efficient and innovative designs has led to a surge in the exploration of unique alternatives to traditional LED wiring harness options. While the conventional LED wiring harness has served its purpose for years, modern demands for sustainability, cost-effectiveness, and enhanced performance are driving manufacturers and engineers to seek out more creative solutions.

This blog will delve into examples of alternative approaches to LED wiring harness configurations, examining how these innovations not only improve functionality and ease of installation but also pave the way for future advancements in lighting technology. By considering these unique solutions, we can better understand the potential for transforming the way we connect and power our lighting systems, ultimately reshaping the industry standards for LED applications.

Advantages of Innovative Wiring Solutions Over Traditional LED Harnesses

Traditional LED wiring harnesses have served their purpose for years, yet the emergence of innovative wiring solutions is reshaping the landscape. One significant advantage of these alternatives is their streamlined design, which minimizes space requirements and reduces the overall weight of installations. This efficiency not only facilitates easier handling and installation but also contributes to better performance in various applications, from automotive to home lighting systems.

Moreover, innovative wiring solutions often incorporate advanced materials that enhance durability and resistance to environmental factors, such as moisture and temperature fluctuations. This results in longer-lasting installations, reducing maintenance costs and enhancing reliability. Additionally, many of these new wiring methods allow for greater customization and flexibility, enabling designers and engineers to create more sophisticated and adaptable lighting systems tailored to specific needs. As the industry shifts towards more sustainable practices, these innovative solutions present a promising alternative to traditional LED wiring harnesses.

Key Technologies Transforming LED Wiring Harness Options

Advancements in LED technology are steadily refining wiring harness solutions, leading to innovative alternatives that enhance efficiency and reduce costs. According to recent reports from the LED Equipment Market Analysis, the global LED lighting market is projected to reach $105 billion by 2025, with a compound annual growth rate (CAGR) of 13.6% from 2020. This surge is largely attributed to the increasing demand for energy-efficient solutions and the evolution of LED wiring harness technologies incorporating cutting-edge materials and designs.

Advancements in LED technology are steadily refining wiring harness solutions, leading to innovative alternatives that enhance efficiency and reduce costs. According to recent reports from the LED Equipment Market Analysis, the global LED lighting market is projected to reach $105 billion by 2025, with a compound annual growth rate (CAGR) of 13.6% from 2020. This surge is largely attributed to the increasing demand for energy-efficient solutions and the evolution of LED wiring harness technologies incorporating cutting-edge materials and designs.

One prominent trend reshaping the landscape is the integration of smart wiring systems that leverage IoT capabilities. These intelligent solutions not only optimize power distribution but also facilitate real-time monitoring of system performance and energy consumption. A report by TechNavio predicts that the introduction of smart technology in LED wiring harnesses could enhance energy efficiency by up to 30%, significantly lowering operational costs and promoting sustainability. Additionally, advancements in materials, such as the use of lightweight, high-temperature resistant plastics, are improving the durability and performance of harnesses in demanding environments, furthering their appeal across various industries.

Cost-Benefit Analysis of Modern Alternatives for LED Installation

The transition from traditional LED wiring harness solutions to modern alternatives has shown significant cost-saving potential for businesses. According to a recent report by MarketsandMarkets, the LED lighting market is projected to reach $105.37 billion by 2025, reflecting a shift in consumer preferences towards more efficient installation options. These alternatives, such as flexible LED strips and wireless control systems, not only reduce the material costs associated with traditional wiring but also lower labor expenses significantly. In fact, a study conducted by McKinsey showed that companies using wireless technology for LED installations can cut labor time by up to 50%, resulting in lower project costs and faster deployment times.

Furthermore, the long-term benefits of these alternatives extend beyond initial savings. A report from the U.S. Department of Energy highlights that modern LED systems can reduce energy costs by up to 75% compared to traditional lighting. This long-term perspective is crucial for businesses looking to maximize their return on investment. By adopting innovative wiring solutions, companies can enhance their operational efficiency while simultaneously contributing to sustainability goals, making the cost-benefit analysis of modern alternatives overwhelmingly favorable in today's energy-conscious market.

Exploring Unique Alternatives to Traditional LED Wiring Harness Solutions - Cost-Benefit Analysis of Modern Alternatives for LED Installation

| Alternative Solution | Initial Cost (USD) | Installation Time (Hours) | Lifespan (Years) | Energy Efficiency (%) | Maintenance Cost (USD/Year) | Overall Rating (1-5) |

|---|---|---|---|---|---|---|

| Flexible LED Strip | 150 | 2 | 10 | 85 | 20 | 4 |

| Smart LED Panels | 300 | 3 | 15 | 90 | 15 | 5 |

| LED Retrofit Kits | 200 | 4 | 12 | 80 | 25 | 4 |

| Wireless LED Controllers | 100 | 1 | 8 | 75 | 10 | 3 |

Comparative Review of Materials Used in LED Wiring Systems

In recent years, the demand for innovative lighting solutions has pushed the boundaries of traditional LED wiring harness designs. This comparative review focuses on the materials used in LED wiring systems, highlighting unique alternatives that offer improved performance and sustainability. Conventional materials like copper remain popular due to their excellent conductivity, but their limitations in weight and flexibility can hinder installation in complex environments.

Emerging alternatives such as aluminum and composite materials are gaining attention for their lightweight properties and resistance to corrosion. Aluminum, while not as conductive as copper, can reduce overall system weight, making it an advantageous choice for applications where weight-saving is critical. Additionally, advancements in polymer-based connectors and insulators have introduced a new dimension of flexibility and durability, allowing manufacturers to create more adaptable wiring solutions. These materials not only enhance functionality but also contribute to longer-lasting, more efficient lighting systems, proving that exploring alternatives is essential in meeting modern electrical demands.

Comparative Review of Materials Used in LED Wiring Systems

Future Trends in LED Wiring: Sustainability and Efficiency Considerations

As the demand for LED technology continues to grow, sustainability and efficiency become paramount considerations in the design and implementation of wiring harness solutions. According to a report by the International Energy Agency (IEA), global LED lighting is projected to save approximately 2,000 terawatt-hours (TWh) of electricity by 2030, significantly reducing greenhouse gas emissions. This shift towards energy-efficient solutions underscores the necessity of evolving traditional wiring harness designs into more sustainable alternatives that can further enhance overall system performance.

One promising trend in this arena is the integration of biodegradable materials in wiring harnesses. Reports indicate that bioplastics can reduce reliance on fossil fuels and lower the carbon footprint associated with manufacturing processes. Moreover, modular designs allow for easy repairs and upgrades, extending the life cycle of lighting systems while minimizing waste.

**Tips:** When selecting LED wiring solutions, prioritize options that leverage recyclable or biodegradable materials. Additionally, consider modular designs that not only simplify maintenance but also contribute to a greener approach to waste management. Embracing these innovative strategies will not only align with sustainability goals but also enhance operational efficiencies within the lighting industry.

Related Posts

-

Unlocking the Technical Specifications of the Best LED Light Wiring Harness for Global Buyers

-

The Ultimate Guide to Choosing the Perfect LED Strip for Your Project

-

How to Choose the Best LED Light Harness for Optimal Performance and Efficiency

-

How to Choose the Best LED Strip Connector for Your Lighting Projects