Understanding the Importance of High Quality LED Wire Connectors for Your Projects

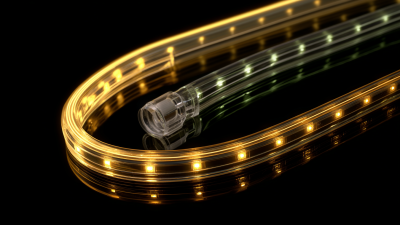

In today's rapidly evolving technological landscape, the relevance of high-quality components in electrical projects cannot be overstated. Among the myriad of essential components, led wire connectors emerge as a crucial element for ensuring safety, efficiency, and reliability in lighting applications. These connectors serve as the vital link between LED light strips and power sources, facilitating seamless connectivity and optimal performance. In this guide, we will delve into the significance of choosing the best led wire connectors for your projects, highlighting their role in enhancing durability, minimizing potential electrical issues, and improving overall project outcomes. Whether you are a seasoned professional or a DIY enthusiast, understanding the nuances of led wire connectors will empower you to make informed decisions and elevate the quality of your electrical installations.

How to Choose the Right LED Wire Connectors for Your Project

When it comes to selecting the right LED wire connectors for your projects, understanding the specifications and application requirements is essential. According to a report by the National Electrical Manufacturers Association (NEMA), more than 70% of lighting applications are now utilizing LED technology, making the choice of connectors a crucial factor in ensuring efficiency and longevity. High-quality connectors not only facilitate optimal electrical connection but also contribute to the overall performance by minimizing energy loss and enhancing safety.

In addition, compatibility with various wire gauges is paramount. As highlighted in the 2022 Lighting Research Center's study, using connectors that accommodate the right wire sizes can reduce the risk of overheating and improve the lifespan of LED systems. Moreover, investing in connectors with proper insulation ratings can protect against environmental factors, ultimately supporting the reliability of your project. By applying these insights and focusing on quality, project managers can select LED wire connectors that enhance both performance and durability.

Understanding the Importance of High Quality LED Wire Connectors for Your Projects

| Connector Type | Wire Gauge Compatibility | Max Voltage (V) | Max Current (A) | Temperature Range (°C) | Application |

|---|---|---|---|---|---|

| Screw Terminal Connector | 18-22 AWG | 300 V | 10 A | -40 to 105 | General Use |

| Quick Disconnect Connector | 20-24 AWG | 250 V | 7 A | -20 to 85 | Automotive |

| JST Connector | 22-28 AWG | 250 V | 3 A | -25 to 85 | Consumer Electronics |

| Waterproof Connector | 18-20 AWG | 600 V | 15 A | -40 to 105 | Outdoor Applications |

| Pin Header Connector | 22-24 AWG | 300 V | 5 A | -30 to 85 | Computers and Robotics |

Tips for Installing LED Wire Connectors Safely and Effectively

When it comes to installing LED wire connectors, safety and effectiveness are paramount. Begin your installation process by selecting high-quality connectors that suit the specific requirements of your project. Ensure the connectors are rated for the voltage and current of your LED system. Reading the manufacturer's specifications is crucial, as using connectors that don’t match your system can lead to poor performance or even hazardous situations.

Next, prepare your wires by stripping the insulation carefully to avoid damaging the conductors. A clean, neat strip will help ensure a strong electrical connection. When connecting the wires, follow the color coding—typically, the black wire is negative and the red wire is positive. Secure the connection properly, using either soldering or crimping methods as appropriate. Lastly, always test the connections with a multimeter before finalizing the installation to confirm that everything is working correctly and safely. This attention to detail helps ensure that your lighting project runs smoothly and effectively.

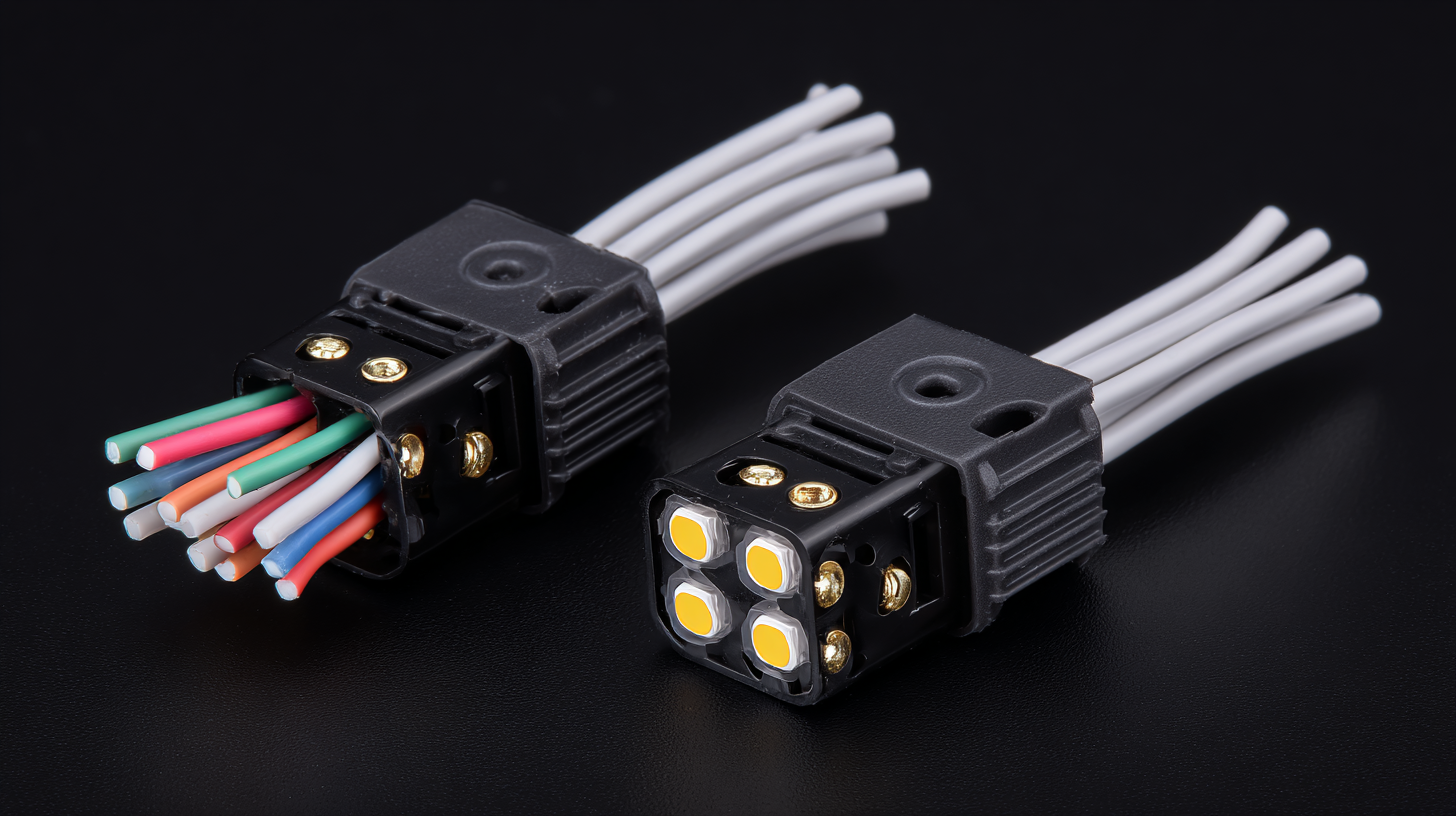

LED Wire Connector Types and Their Usage

Common Mistakes to Avoid When Using LED Wire Connectors

When working with LED wire connectors, it's crucial to avoid common mistakes that can compromise the integrity of your projects. One frequent error is using the wrong connector size for your wires. Using connectors that are either too large or too small can lead to poor connections, resulting in flickering lights or complete failures. Always ensure that the connector matches the wire gauge for optimal performance.

Another mistake to watch out for is inadequate stripping of the wire insulation. Properly stripping the wire ensures a secure connection, but stripping too much or too little can lead to exposure of the wires, which may cause shorts or inefficient power transfer. Aim for a clean strip that leaves enough copper exposed to make solid contact without risking a short circuit.

Tips: Before making a connection, double-check that the wires are clean and free from corrosion. Additionally, consider investing in high-quality connectors specifically rated for LED applications. This small investment can save you from headaches in the long run by improving reliability in your project.

Maintenance Guidelines for Prolonging the Life of LED Wire Connectors

Proper maintenance of LED wire connectors is crucial for ensuring their longevity and optimal performance in any project. Regularly inspecting these connectors for signs of wear and corrosion can help detect issues before they lead to failures. Look for discoloration, fraying wires, or loose connections to determine if replacement or repairs are necessary. Keeping the connectors clean and free from dust or debris will also enhance their conductivity and reliability.

Another important aspect of maintenance involves ensuring that connectors are not subjected to excessive strain or tension. Using appropriate strain relief measures can protect the wires from stress that might compromise the connection. Additionally, when installing or removing connectors, be gentle to prevent damage. It's also advisable to keep connectors stored in a dry and temperature-controlled environment to avoid exposure to harsh conditions that can lead to deterioration.

By following these guidelines, you can significantly extend the life of your LED wire connectors and maintain the integrity of your projects.

How to Troubleshoot Issues with Your LED Wire Connectors

When working on LED projects, it's crucial to understand that even the best designs can falter due to poor connectivity. Troubleshooting issues with LED wire connectors is therefore an essential skill for any technician or DIY enthusiast. According to a report by the National Institute of Standards and Technology, improper connections can lead to up to 30% decrease in LED performance, manifesting in flickering lights or complete failures. To systematically identify issues, one should firstly inspect the physical connections. Look for any signs of corrosion, looseness, or fraying, as these can critically impair the electrical flow.

Another common problem involves compatibility between connectors and LED strips. According to a study by the Lighting Research Center, mismatched connectors account for nearly 25% of installation issues among professionals. Always verify the specifications of both the connectors and the LED components during the purchasing process, ensuring that they meet the required voltage and current ratings. Utilizing a multimeter to test for continuity can also help in pinpointing the exact location of the fault in your circuit, enabling you to rectify issues before they escalate into larger, more expensive problems.

Related Posts

-

Top Strategies for Enhancing Performance with LED Connectors

-

Exploring Unique Alternatives to Traditional Light Strips for Your Home Decor

-

What Makes Wire LED Lights the Future of Illumination

-

Exploring the Future of Custom LED Innovations at the 138th Canton Fair 2025 in China

-

Exploring Unique Alternatives to Traditional LED Wiring Harness Solutions

-

How to Choose the Right LED Light Wiring Harness for Your Projects