Unlocking the Technical Specifications of the Best LED Light Wiring Harness for Global Buyers

In recent years, the demand for energy-efficient lighting solutions has surged, positioning LED technologies at the forefront of innovation in the lighting industry. According to a report by Grand View Research, the global LED lighting market is expected to reach USD 105.75 billion by 2025, highlighting the pivotal role of components like the LED light wiring harness in optimizing performance and safety.

A high-quality wiring harness is essential for ensuring seamless connectivity and reliability in various applications, from automotive to general lighting. As global buyers seek to enhance their lighting systems, understanding the technical specifications of these harnesses becomes critical. This blog aims to provide a comprehensive comparison of the best LED light wiring harness options available in the market, helping consumers make informed purchasing decisions based on performance, durability, and compatibility.

The Evolution of LED Light Wiring Harness Technology for Improved Performance

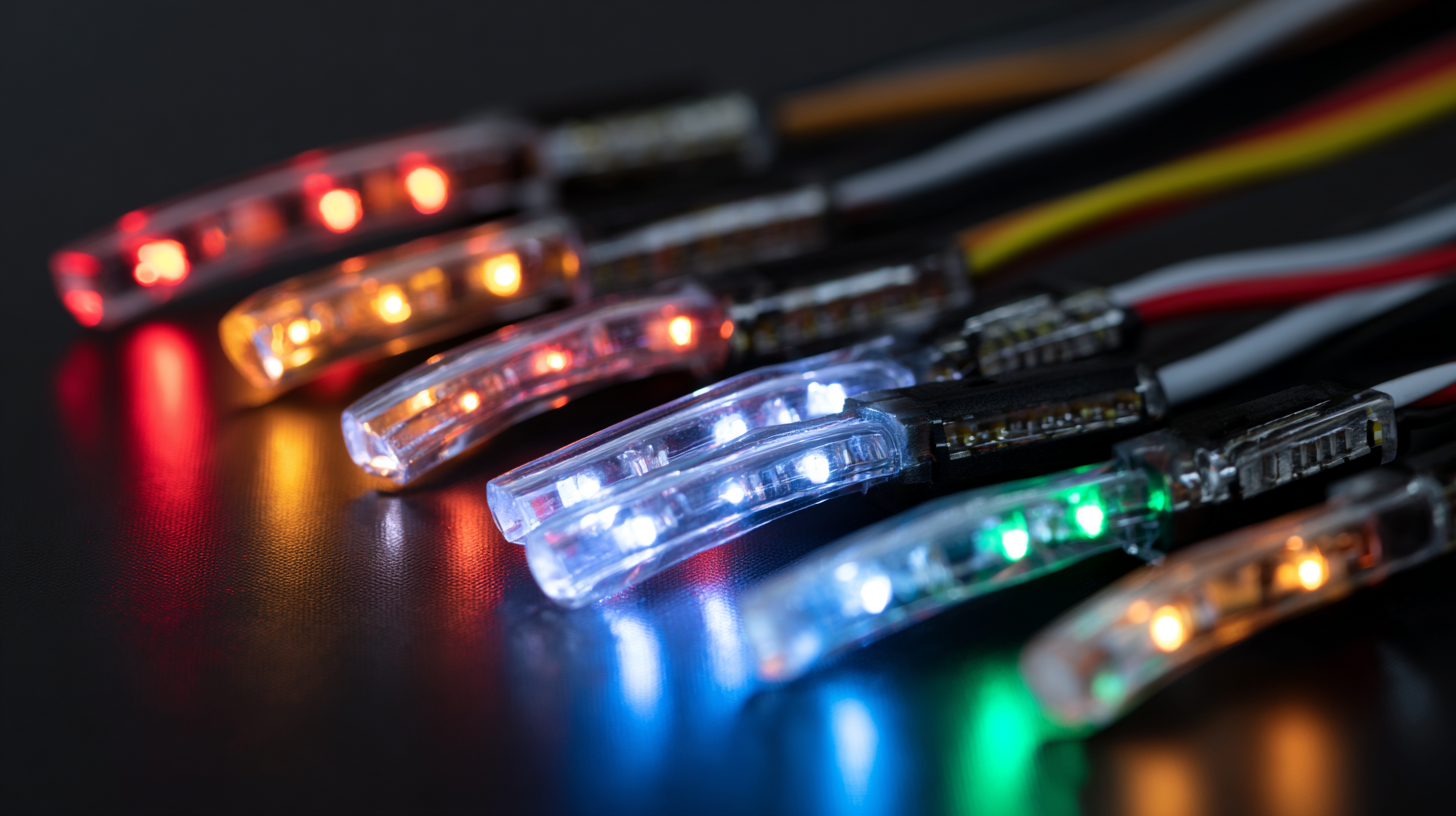

The evolution of LED light wiring harness technology has significantly enhanced performance and reliability in lighting systems. Originally, wiring harnesses were basic, primarily serving to connect power sources to lighting fixtures. However, with advancements in LED technology and the growing demand for energy-efficient solutions, these harnesses have transformed. Today’s LED light wiring harnesses are designed with intricately engineered materials that not only improve conductivity but also withstand various environmental conditions, ensuring longevity and consistent performance.

Moreover, modern wiring harnesses incorporate innovative features such as integrated fuses and smart connectors that provide added safety and efficiency. With the increasing complexity of LED systems, including features like programmable lighting and dimming functions, these harnesses facilitate seamless integration and user-friendly operation. This evolution reflects the broader trend towards smart and sustainable technology, allowing global buyers to leverage advanced solutions that meet their needs while contributing to energy conservation efforts. The focus on high-performance materials and designs signifies a promising future for LED lighting applications across various industries.

Key Features to Look for in High-Quality LED Light Wiring Harness

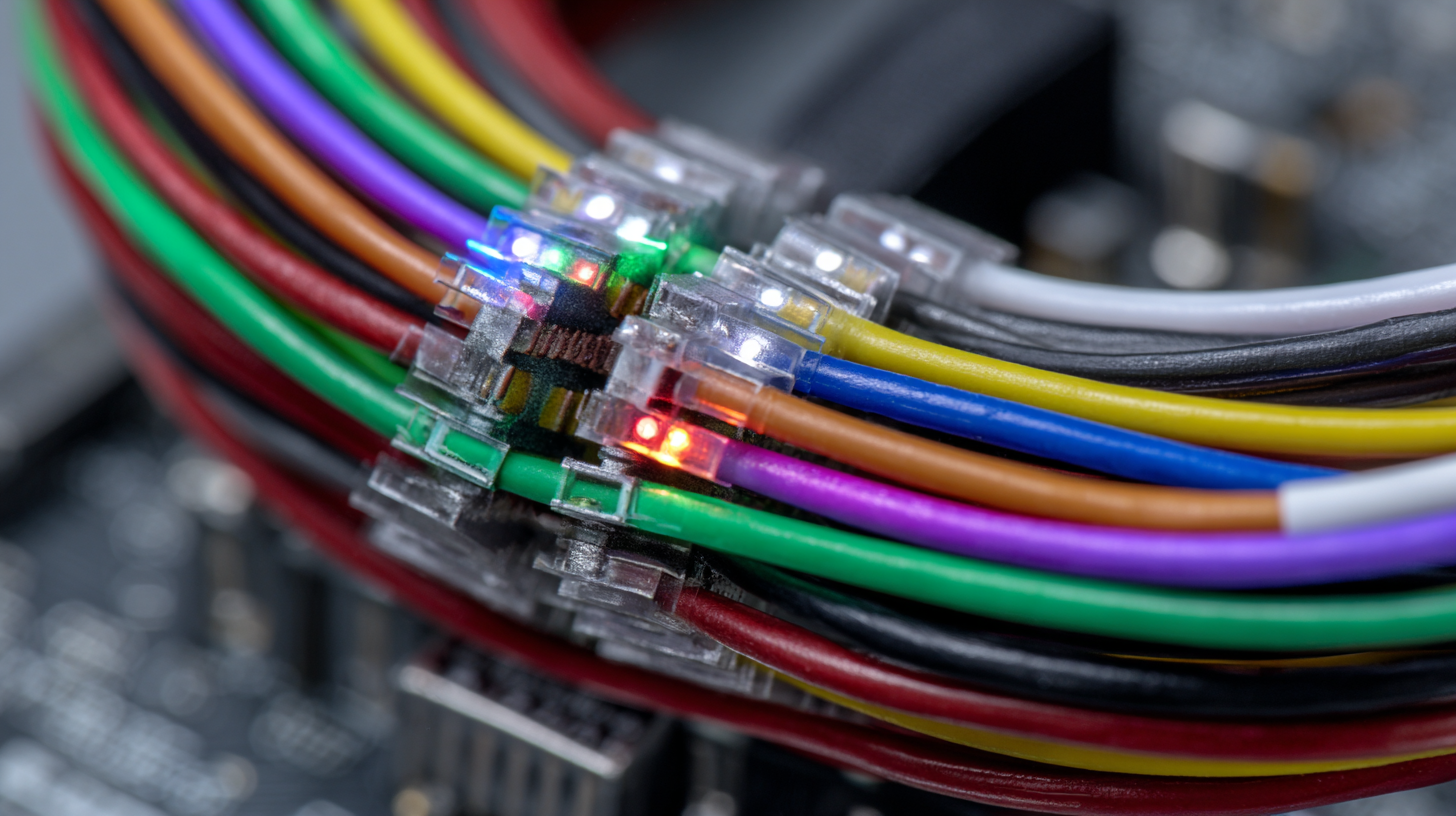

When selecting a high-quality LED light wiring harness, understanding the key features is crucial for ensuring optimal performance and safety. One vital aspect is the gauge of the wiring. According to a study by the Electrical Safety Foundation International, appropriate wire gauge minimizes voltage drop and reduces the risk of overheating, especially in high-power LED applications. A harness with at least 16-gauge wiring is recommended for most automotive LED lighting setups, ensuring that your lights operate efficiently without compromising on brightness.

Another important feature to consider is waterproofing capabilities. With an increasing number of vehicles being used in diverse environments, harnesses with IP67 or IP68 ratings provide essential protection against moisture and dust. According to a report from Frost & Sullivan, a robust wiring harness can enhance the lifespan of LED lights by up to 50%, making it a smart investment for long-term use.

Tips: Always check for quality connectors and heat-resistant materials in a wiring harness. Additionally, consider options with integrated fuses for enhanced safety and protection against electrical surges. These features not only contribute to the longevity of your LED lights but also ensure a safer driving experience.

Understanding Compatibility: How Global Buyers Can Ensure the Right Fit

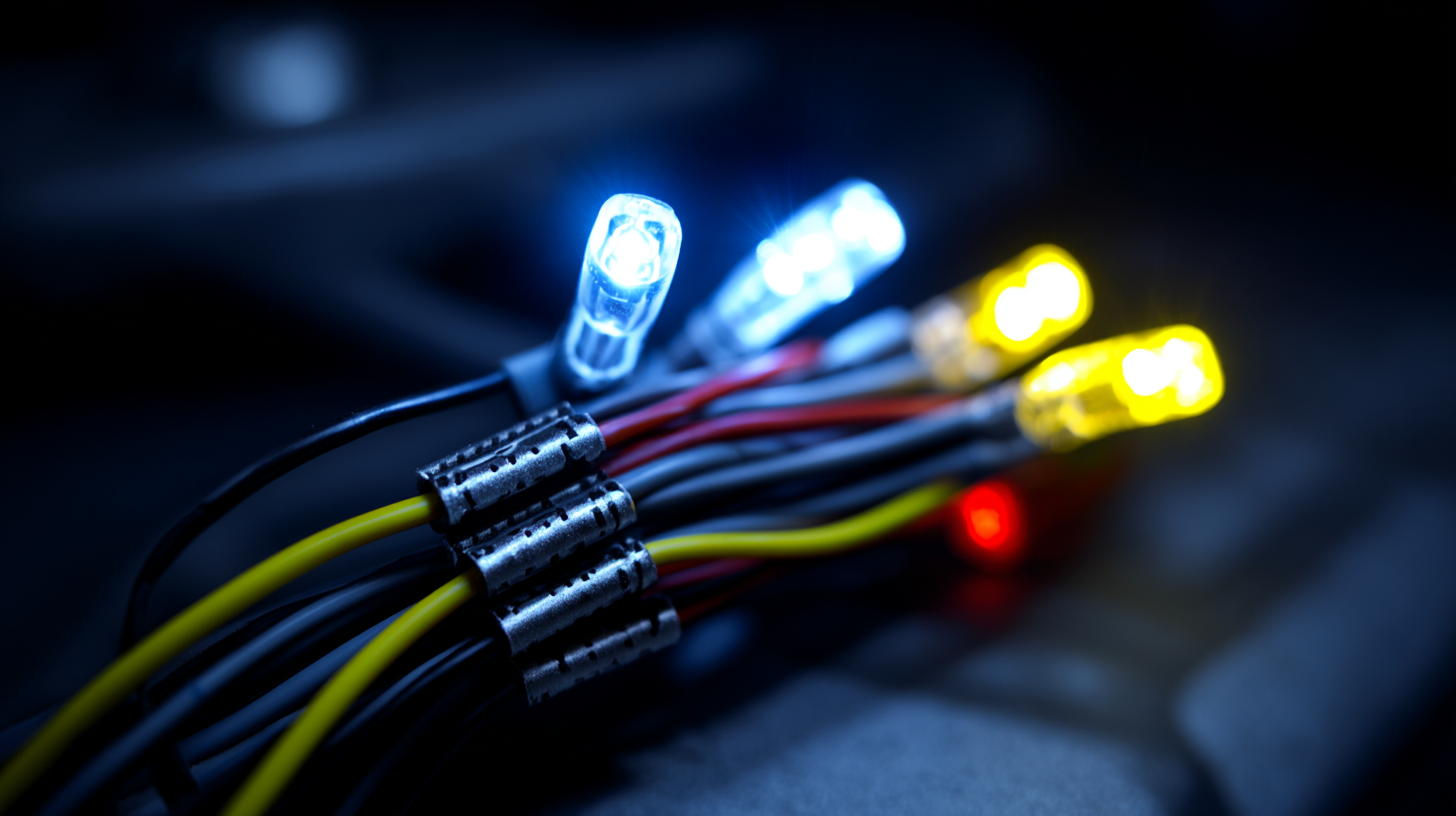

When it comes to selecting the best LED light wiring harness, compatibility is key for global buyers. Understanding the specific technical specifications of various models can help ensure that your lighting setup will work seamlessly. Manufacturers often provide detailed compatibility charts that list which vehicles or applications each harness supports. By cross-referencing these details with your requirements, you can avoid potential pitfalls associated with mismatched connectors, voltage ratings, and wire gauges.

Additionally, it is crucial to consider the five attributes of compatibility and trust outlined for buyer-supplier relationships. These factors not only enhance the likelihood of a successful transaction but also promote long-term partnerships. For instance, assessing the supplier’s reliability and understanding their return policies can further ensure that you’re making a sound investment in the right harness for your needs.

As the market for LED lighting solutions continues to grow, being informed and cautious in your selection process will pay off, resulting in a more satisfactory lighting experience.

The Importance of Certifications and Standards in LED Light Wiring Harness Production

When considering the purchase of LED light wiring harnesses, certifications and standards play a crucial role in ensuring product quality and safety. Manufacturers that adhere to recognized standards, such as IEC, UL, or CE, demonstrate their commitment to delivering reliable products. These certifications not only reflect compliance with industry regulations but also inspire buyer confidence in the durability and performance of the harnesses.

Tips for selecting the best wiring harness include checking for certifications and testing reports from reputable organizations. Additionally, buyers should look for products that specify compatibility with various LED systems, ensuring versatility for different applications.

Always prioritize harnesses with clear product labeling and specifications, as these details can highlight the quality of materials used and the manufacturing process. A trustworthy manufacturer will openly share information regarding the certifications their products hold, which can assist global buyers in making informed decisions.

Insights into Supply Chain Dynamics: Sourcing from China for Global Markets

Navigating the complexities of the supply chain is critical for global buyers sourcing LED light wiring harnesses, particularly from China. According to a report by ResearchAndMarkets, the global LED market is projected to reach $162 billion by 2026, driven in part by the rising demand for energy-efficient lighting solutions. This demand has led to an acceleration of production capabilities in China, which currently accounts for over 60% of the world's LED manufacturing output. Buyers must stay updated on the dynamics of sourcing, as factors such as tariff changes and logistics challenges can significantly impact pricing and availability.

In addition to the manufacturing capabilities, understanding the regional supply chain infrastructure in China is essential. The country possesses a robust network of suppliers and manufacturers, often centralized in regions like Guangdong, where over 1,500 LED companies operate. This concentration fosters a competitive environment, leading to improved pricing and innovation. However, global buyers are also advised to conduct thorough due diligence to evaluate supplier reliability and compliance with international standards, particularly as the market continues to evolve in response to technological advancements and changing consumer preferences. Careful management of these dynamics can result in significant advantages in sourcing high-quality LED lighting solutions.